Here is a bunch of scrap brass I've been collecting. Its mainly just pipe fittings and short lengths of pipe. I remove all of the non-brass parts such as rubber washers and stuff. There's even a decorative "bunny crossing" sign I found somewhere.

I decided to cast a brass incense holder. I figured if I'm casting brass it should be something really nice... something I can give as a gift if I choose. The wooden one was made in China and the brass one is my casting. Take a look at how I did it...

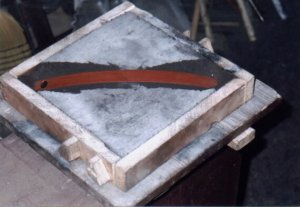

Since the pattern was curved I had to use a method of molding called "coping down" this is where you carve out molding sand until you reveal the parting line of the casting. You can see the sand cut away here in the drag.

The cope sand is rammed in as usual and it conforms to the shape of the drag just like with any other sand mold. Here you can see that.

Here's the brass loaded into the crucible with the furnace blasting at it. I mainly used some fittings but I melted the bunny sign also. The lid is removed for the picture.

I'm finally pouring the metal. This was 30 minutes after loading the crucible. Yes I know I should be wearing gloves for safety but I like living on the edge... (Don't try that at home).

I always pour metal from the flower pot furnace with these slip joint pliers and with aluminum its absolutely no problem. The heat radiating off is hardly noticed. This is not the case with brass! The radiant heat was pretty uncomfortable (to say the least) I don't plan on pouring it like this again.

Here you can see smoke and steam escaping through the vent holes. The molding sand I'm using here is homemade greensand (where the steam comes from) mixed with the remainder of my oil bonded sand (the smoke is the remainder of the oil burning out).

This is the first attempt at casting the incense holder, the metal cooled prematurely. I only used a 3/4-inch sprue so that was part of the problem (too small I think). Also before I poured the metal I was just holding the crucible out of the furnace for about 10 seconds preparing for the picture of the actual pour so that allowed the metal to cool somewhat also.

Here is the bottom of the successful casting with a little bit of finishing done to it (sprue cut off and ground down a bit). Just before pouring the metal I threw a small piece of zinc sheeting into the melt to replace some of the vaporized zinc. As soon as it hit the molten brass it flashed into a green flame and smoke so I don't know if it was effective. It seemed like this casting was a brighter yellow than the first (failed) attempt which I didn't add zinc to, but that may have just been my imagination.

Here is the finished casting with the sprue cut off next to it and the pattern for comparison.

Here's the incense holder in use next to some small elephant ornaments. Go to the Next page.