I start with a piece of iron pipe the diameter I want the crucible to be. I found this piece with several others discarded at an industrial renovation site. There's also a steel plate from which disks used for the base are cut from. If you look closely you may be able to tell that the plate is actually welded together from three smaller plates. Yes I did that!

Here I'm cutting the disks with an arc cutting electrode. Basically its just using the welding machine with it cranked up scary high (well its not really scary...) with a slightly larger electrode. The metal melts just like while welding but the amperage is so much higher that the molten pool gets blown out the way leaving a cut (No I did not invent this process, and yes it is a legitimate use of the welder).

Here's the ragged cut...I never said arc cutting was pretty. Besides I'm not even close to being a pro, I've only done this about 3 times.

Even with a ragged cut the base fits the pipe perfectly and is ready for welding.

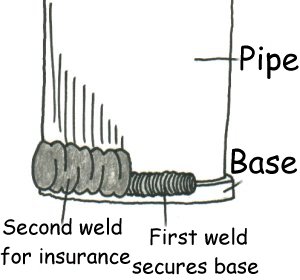

This is the way I weld the base to the pipe. I first tack weld it at several places, then I go around it with the first weld to secure the base firmly. Next I use a "weaving" pattern with the electrode to create a wide strong connection to ensure the crucible's integrity. Initially I didn't put the second weld on my first crucible and somehow the single weld split. Now I spend the extra time on all of them I make.

Since I was in the crucible making and reparing mood I decided to alter my big old standby crucible. It was for the better. It was so large that I couldn't keep it full without the metal cooling anyways. Besides that thick pipe cap base absorbed too much heat before melting the metal.

This is the last stop on our crucible making tour. Here you can see my four crucibles and of course the modified version of my old standby. Its now six inches tall and I like it a lot better now. I plan to use the shortest one for brass only.

Part 1: Building iron and steel crucibles - Part 2: Rebuilding the "old standby"